Here at makewine.co.nz we hope you will love making and drinking your own homemade wine as much as we do!

We also think the only silly question is one you don't ask; so if you've bought your products from us please email us at info at makewine dot co dot nz. We will get back to you within 24 hours (usually sooner).

Assemble your home winemaking equipment

The recipe below is for fruit wine and wine made from eating grapes. If you have winemaking grapes please use these instructions for making wine from winemaking grapes.

This is a generic recipe and will work for fruit wine. However, you may have a recipe which calls for slightly different timeframes and quantities. If so, please follow your own recipe.

If you are making wine from citrus fruits or any other acidic fruit, don't add citric acid at primary fermentation. You can add citirc acid at the end of fermentation if you think you wine needs more acidity.

Day 1 (extraction)

Day 2 (primary fermentation)

Days 3+ (primary fermentation)

When your must stops bubbling:

In the carboy

"Racking"means to siphon the wine off the sediment.

Racking will not help your wine clear.

Racking should not [usually] be undertaken whilst your wine is still fermenting.

Racking is best done sparingly. Every time you rack, you will lose wine, your wine will be exposed to oxygen (usually not advantageous), and may be exposed to unwanted micro-organisms.

You can use an auto-siphon or siphon manually:

Up to you how long you leave it. Many books say leave it for months, here at makewine.co.nz, we don’t have much patience so we’re usually drinking it in 1-4 weeks time. Some wines will improve and mellow with age, many fruit wines are better drunk young when they still have their fruity characteristics.

Safety:

To make a 10% solution

Use 10% solution to sterlise must

Use 2% solution to sterlise equipment

Use the same method as above:

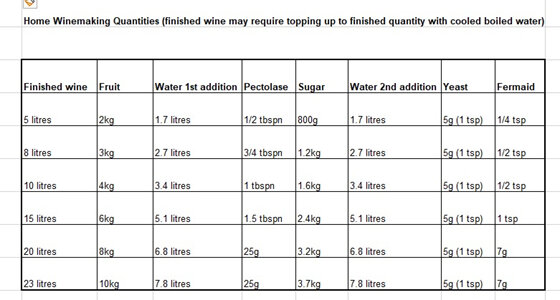

Fruit: 4+ kgs

Pectolase: 1 tbsp (about 11g)

Yeast: 5g

GO-FERM Protect: 6g (optional)

Sugar: 1.8 kgs

Citric Acid: 2 tsp (about 11g) (optional)

Tannin: 1/2 teaspoon (optional)

Fermaid A: 1/2 tsp (about 4g) (or Diammonium Phosphate 10g)

Use the same method as above:

Fruit: 10+ kgs

Pectolase: 25g

Yeast: 5g

GO-FERM Protect: 6g (optional)

Sugar: 4 kgs

Citric Acid: 25g (optional)

Tannin: 1 - 1.25 teaspoon (optional)

Fermaid A: 7g (or Diammonium Phosphate 25g)

You can purchase ready-made home winemaking ingredients kits from makewine.co.nz which are great if you've never made wine before.

You can also purchase your home winemaking ingredients in bulk which is very economical if you are making wine regularly.

© 2011-2023 makewine.co.nz